Want To Save An Industry And The Environment? Take A Second Look At Hydrogen-Combustion Engine Cars

By Jacob Doyle

Switching automobile production from gasoline-powered internal combustion engine vehicles to those driven by hydrogen-powered internal combustion engines could make a great deal of sense for the world’s car makers as well as oil producers and the environment. The change could bring a considerably smaller shock than making a wholesale switch to production of electric vehicles (EVs) powered by lithium-ion batteries or even fuel cells. And it would reduce carbon emissions.

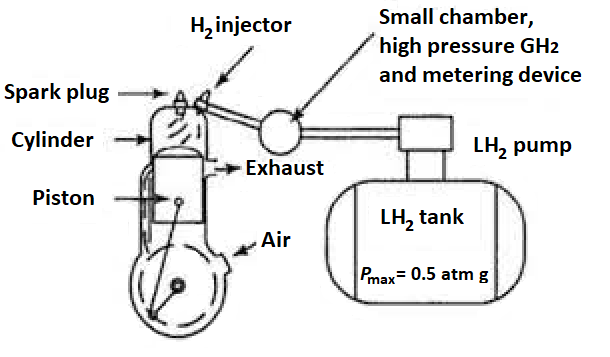

A hydrogen-powered car that uses an internal combustion engine is mechanically identical to a conventional gasoline-powered car in most ways. Hoses and sparkplugs would need to be changed, but the biggest difference is the fuel tank. While safe, effective storage of hydrogen has been historically difficult to achieve, a team at Northwestern University announced in April 2020 a new solution for this using a “metal-organic framework” (MOF) with nanoscopic pores that can retain the gas in a sort of sponge rather than a tank.

Assuming this hydrogen sponge or something similarly viable could replace conventional fuel tanks, then just minor alterations would need to be made to the designs of current car models to switch them to hydrogen power. This promises a much smoother transition to emission-free vehicles than going over completely to electric vehicles, which are radically different mechanically. Many thousands of engineers and mechanics would get to cheap their jobs without needing to be reeducated.

Cheap, Oil Industry-friendly Hydrogen

What’s more, hydrogen fuel can be generated directly from petroleum with negligible carbon emission. And if oil is the feedstock of hydrogen vehicle fuel, then existing petroleum supply chains could remain in place. Only refineries would require major conversions: instead of brewing crude into gasoline, they would release high-purity hydrogen from crude oil using microwaves or some other proven method, which research indicates could actually be more cost- and resource-efficient than producing gasoline. Tanker trucks and filling stations would need to be refitted with hydrogen sponges. But if this sponge material could be mass produced in a manner resembling polyurethane foam, then this needn’t be a gargantuan undertaking.

Historically, the biggest arguments against hydrogen-combustion engines have centered on the cost and other challenges of hydrogen fuel, toxicity and the relative inefficiency of such an engine when compared to an electric car powered by a hydrogen fuel cell.

Regarding cost, hydrogen is only expensive compared to gasoline and diesel when it’s derived from water using electrolysis, a process that requires more energy to release the hydrogen than the hydrogen delivers as a fuel. If hydrogen is derived from crude oil or natural gas, it needn’t cost more than gasoline and could even cost less to produce. Eventually, as more wind and solar electricity production come online, then hydrogen could be derived from water in a cost-effective way, seeing as sun and wind are themselves cost-free energy feedstocks. In the meantime, hydrogen can in principle be generated from petroleum so that cost alone needn’t be a barrier to adopting it as a fuel to replace gasoline and diesel. Moreover, the process would protect the existing fuel industry and the myriad jobs it retains.

Toxicity is another issue. While exhaust from a hydrogen-combustion engine contains neither CO2 nor CO, it has been demonstrated to contain NOx, a highly toxic gas. The NOx byproduct has often been cited as a reason to abandon hydrogen-combustion engines as the car engine of the future. But it ain’t necessarily so. By slowing down the rate at which air and hydrogen fuel mix, NOx formation can be dramatically minimised. Another method demonstrated to lower NOx emissions is exhaust gas recirculation (EGR). So NOx need not be a deal-breaker, either.

Efficiciency? How Efficient is Saving an Industry?

As for the relative inefficiency of a hydrogen-combustion engine car versus a hydrogen-fuel cell-powered electric car, this depends on what efficiency you happen to be measuring. If you’re comparing a pair of cars, a fuel cell EV and a hydrogen ICE, then the fuel cell EV will demonstrate a more efficient use of its hydrogen fuel as measured in a distance over fuel quantity ratio. But expand your measure of efficiency to cover an entire industry and things start looking different.

The billions of dollars, euros, and yen invested in factories, R&D, maintenance, distribution and marketing of the cars currently on the road would largely be wasted if it were suddenly decreed that these cars must be junked in favor of electric cars powered by fuel cells (or, for that matter, lithium-ion batteries). But if a structured transition were introduced whereby existing and planned models of gasoline and diesel powered ICE cars would be modified to run on hydrogen without actually replacing their powertrains, then those billions could still be put to good use and people could go on working in the jobs they currently have.

Hydrogen or Gasoline? Both?

Another prospect worthy of strong consideration is to develop “flexi-fuel” ICE cars that can operate with either on gasoline OR hydrogen as a source of fuel. Currently, there are many vehicles on the road that give drivers a ready choice of using either gasoline or liquified natural gas to power them, as their engines are so-equipped and they hold tanks for each fuel. So, the same flexibility could therefore be installed on a flexi-fuel gasoline/hydrogen car.

Getting started

The place to start such an endeavor is to launch a study. It would aim to reveal all the basics:

- Environmental benefits of switching from hydrocarbon ICE to hydrogen ICE vehicles

- Feasibility and costs of altering manufacturing to produce hydrogen ICE vehicles instead of hydrocarbon ICE vehicles

- Feasibility and costs of ramping up production of newly developed safe and effective means of storing hydrogen, both in hydrogen ICE vehicles themselves, and in tanker trucks, at filling stations, etc.

- Feasibility and costs of setting up networks of hydrogen distribution stations.

- Feasibility and costs of generating hydrogen, both from fossil-fuel sources and by other means.

The parties with both money to spend and the most to gain from this study are the automakers and the petroleum producers. Why? For the simple reason that putting hydrogen ICE vehicles would keep them both in business for the reasons made clear above. Finding a suitable institute or university to conduct this study shouldn’t be difficult. Issuing a tender in the right Twitter groups should supply a host of worthy candidates.

The sooner we get going, the better for the industries and life on Earth.